en

en

Pharmaceutical Project Solutions

Combined Heat and

Pharmaceutical Project Solutions

Combined Heat andPower Plant

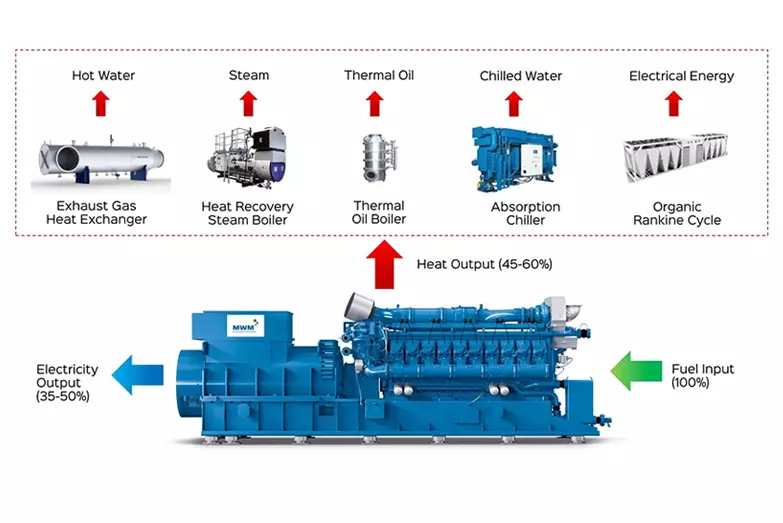

A fuel source (fossil or renewable) is combusted, and the energy produced is used to drive a prime mover (reciprocating engine or gas turbine) which produces mechanical power and heat. The mechanical power is converted into electricity via an alternator and the heat is available to use directly or converted to meet the requirements of the site.

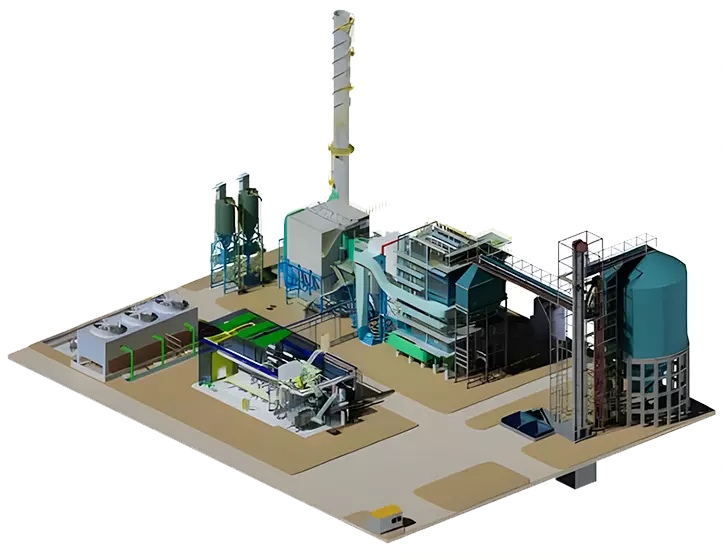

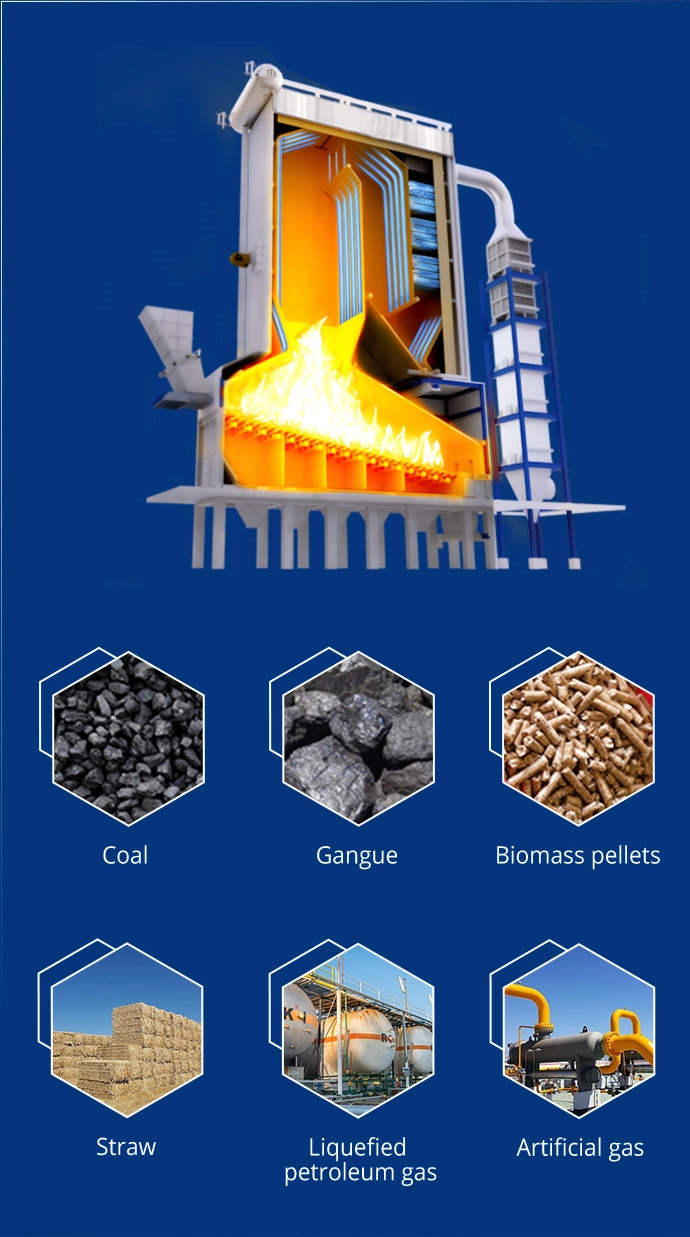

Products applying step grate technology can burn various types of fuels such as biomass, industrial waste, and municipal solid waste.

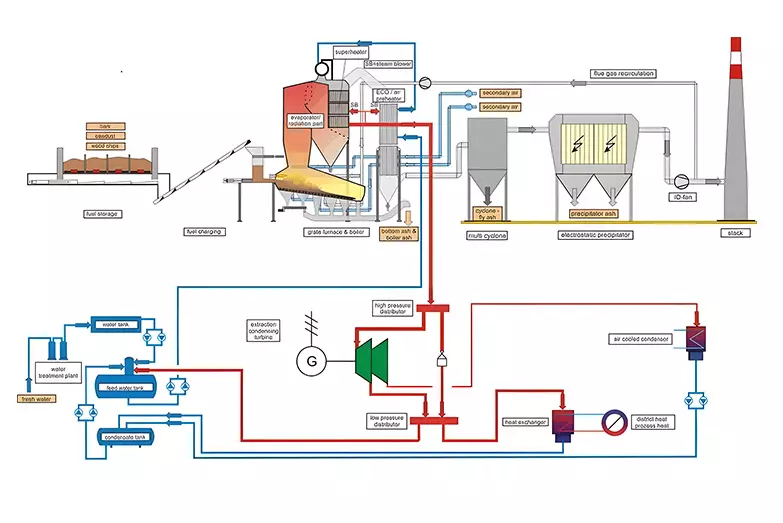

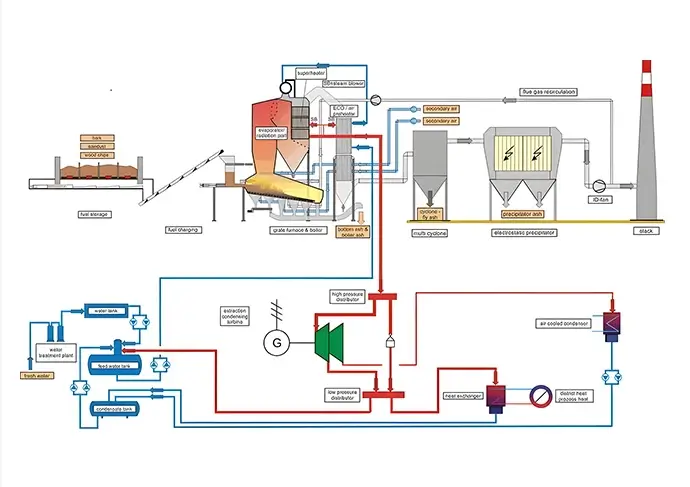

The basic structure of the cogeneration (CO-GEN) thermal power system includes the following components:

- Main equipment: Boiler, turbine, condenser, boiler feed pump.

- Auxiliary equipment: Cooling tower, circulating water pump, condensate pump, deaerator, heat exchanger.

The turbine is a heat engine that converts the thermal energy of steam into rotational mechanical energy. High-pressure and high-temperature steam generated from the boiler enters the turbine, where it undergoes isentropic expansion, producing mechanical work. The reduction in energy of the steam is equal to the work generated by the turbine.

If your organisation utilises power, heat, steam, cooling, and CO2 in your operations and processes, then CHP, Trigeneration, or Quadgeneration should be considered part of an energy strategy. It doesn’t fit every organisation, but where it does, CHP can deliver substantial benefits such as:If your organisation utilises power, heat, steam, cooling, and CO2 in your operations and processes, then CHP, Trigeneration, or Quadgeneration should be considered part of an energy strategy. It doesn’t fit every organisation, but where it does, CHP can deliver substantial benefits such as:

The above are just some of the many benefits of CHP compared to traditional means of separately generating power and heat.

Improve CHP energy efficiency

Thermal efficiency of cogeneration can be improved by using biomass boilers.

Lower CHP CO2 emissions

Thermal efficiency increase of your CHP results in CO2 emission reduction.

Decrease CHP fuel costs

By recovering additional waste heat, less fuel is needed to achieve the required thermal duty of your CHP.DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!

A gas engine or gas turbine is used to generate power and heat. Waste heat from the flue gas is recovered to generate steam or hot water. A typical CHP is already equipped with an economiser to preheat boiler feed water. The flue gas temperature downstream of this economiser typically tends to be >120 °C, which means energy loss.

Depending on fuel type, heat exchangers may suffer from cold spot corrosion due to relatively cold tube skin temperatures. This limits heat recovery. Enhancing further thermal efficiency is possible by installing a corrosion resistant economiser which recovers additional heat from the flue gas. This results in extra energy savings.

Conventional heat exchangers suffer from mechanical failure due to stresses that are developed by thermal expansion. This results in leaking equipment and loss of heat recovery.

In the current era of industrialization, the demand for combined heat and power (CO-GEN) in various manufacturing plants, industrial complexes, and factories is immense. Typical applications of CO-GEN systems in plants include:

The demand for steam for drying products is significant, especially in industries like paper mills where the paper production process typically involves using steam at a pressure of around 10 barg with a temperature of 185°C. Various equipment within the plant consumes a substantial amount of electrical energy, such as rollers, drying machines, water pumps, etc.

The key applications include wood drying, sawmill operations, steam generation, wood pellet production, and biomass utilization. CHP systems offer significant benefits such as reduced energy costs, improved energy efficiency, and lower environmental impact, especially when the plant utilizes its biomass waste as fuel.

Including efficient use of rice husk biomass, lower energy costs, improved plant efficiency, and reduced environmental impact. The co-generation system provides both electricity and heat for rice milling, drying, parboiling, and other processes, making it a sustainable and cost-effective solution for rice processing operations.

Co-generation in sugar cane mills efficiently utilizes the available biomass (bagasse) to produce both electricity and steam for internal processes, creating a self-sufficient, sustainable, and profitable operation. The ability to export surplus electricity to the grid, coupled with the environmental benefits of reducing carbon emissions, makes co-generation an essential component of modern sugar mill operations.

From secondary planning, groundwork, steel fabrication to completion. The combined heat and power plant, now operational, provides 98% of the region's electricity and heat and will reduce emissions by 400 tonnes. There is an option to upsize the cogeneration, but careful consideration must also be given to creating available space for future engine upgrades and potential future hydrogen equipment.

Consult customer service

Understand the needs

Planning and design

Manufacturing

Technical installation

Later maintenance

CHP (Combined Heat and Power) is a system that simultaneously generates electricity and useful thermal energy from a single fuel source. Also known as cogeneration, CHP captures the heat that would typically be wasted in traditional power generation and uses it to provide heating or cooling, resulting in more efficient use of fuel.

Planning for Combined Heat and Power (CHP) systems involves key factors such as energy demand assessment, technology selection, site conditions, regulatory incentives, and long-term maintenance. Effective CHP planning ensures energy savings, reduced emissions, and improved energy resilience for industrial and commercial facilities.

CHP is ideal for facilities with high and constant demand for both electricity and thermal energy, such as hospitals, manufacturing plants, data centers, and universities. It's also beneficial when looking to reduce energy costs, lower carbon footprints, or increase operational resilience during power outages.

CHP can be renewable if it uses renewable fuels like biomass, biogas, or hydrogen. However, it is not inherently renewable, as many systems operate on natural gas or other fossil fuels. Transitioning CHP systems to run on renewable energy sources can make them more sustainable and reduce carbon emissions.

CHP systems are typically installed in locations with high, stable energy demand and where there is space for the equipment, such as industrial plants, hospitals, large commercial buildings, or district energy systems. It's important to assess the thermal and electrical load of the site to ensure optimal performance and energy savings.