Fangkuai Group has a domestic Class A boiler manufacturing license issued by the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Over the years, its development has been quality-oriented, and has successively obtained a number of authoritative quality certifications.

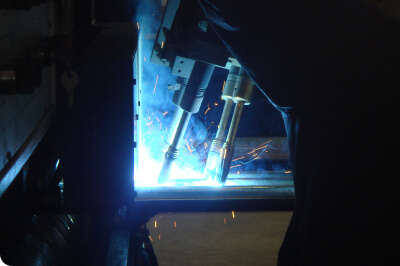

Fangkuai Group insists on using sophisticated equipment and technology to ensure operation accuracy, improve rigidity and surface finish, reduce wear and tear, ensure excellent performance, and ensure stable and reliable manufacturing quality.

A new type of environmentally friendly combustion method, which mixes air and gas evenly, burns quickly and thoroughly, and stirs evenly to make the mixing more complete. Fangkuai Boiler grasped the pulse of the times and followed the concept of environmental protection, and launched a fully premixed ultra-low nitrogen gas boiler with NOX emissions below 9ppm, far lower than the requirements of the "Beijing Boiler Air Pollution Emission Standard" published in Beijing.

In this combustion method, the gas is fully burned, heated evenly, and there is no local high temperature, which avoids the formation of nitrogen oxides and carbon monoxide. The burner has a simple structure and is easy to operate. The user only needs to operate the switch of the boiler control cabinet to automatically start the operation; the full premixed burner can realize proportional adjustment, and the maximum adjustment range can reach 20-100%.

Flue gas recirculation is one of the technologies to suppress nitrogen oxide emissions. Part of the exhaust gas is returned to the air supply system to reduce the oxygen concentration in the mixture and act as a heat absorber to prevent the combustion temperature from becoming too high, thereby suppressing the formation of nitrogen oxides. The flue gas circulation rate is usually 5-20% of the total exhaust gas, reducing NO production by 10-90%. This method is used in stationary combustion facilities such as boilers as a technique for suppressing NO production.

The flue gas condensation waste heat recovery device uses low-temperature water or air to cool the flue gas to reduce the flue gas temperature. The water vapor in the flue gas condenses near the heat exchange surface area, and simultaneously realizes the sensible heat release of the flue gas and the latent heat of water vapor condensation. The water or air in the heat exchanger absorbs heat and is heated to realize heat recovery and improve the thermal efficiency of the boiler. Integrated layout saves more floor space. As the heat surface, the spiral fin tube has high heat exchange efficiency, sufficient heating surface, and low system resistance on the flue gas side, which meets the requirements of ordinary burners.