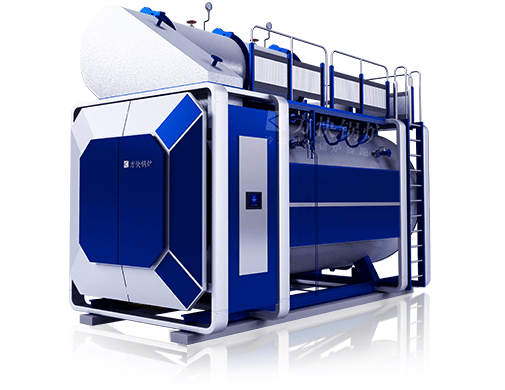

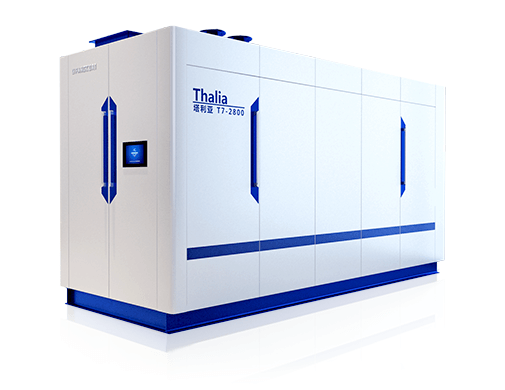

The boiler installs the energy-saving device, further recovery of low-grade heat, improve the overall thermal efficiency of the boiler.

The spirally corrugated tube strengthen the disturbance of flue gas,high heat transfer efficiency.

The boiler adopts the fully automatic low nitrogen burner and flue gas recirculation system (FGR) technology. The fuel is fully burned, and the NOx emission can be reduced to below 30mg/m³.

Adopts advanced corrugated furnace to increase heat transfer area and satisfy the free expansion of the furnace after being heated,while the corrugated furnace structure enhanced smoke disturbance, heat transfer and combustion enhancement.